ecosphere: usual application from the silo

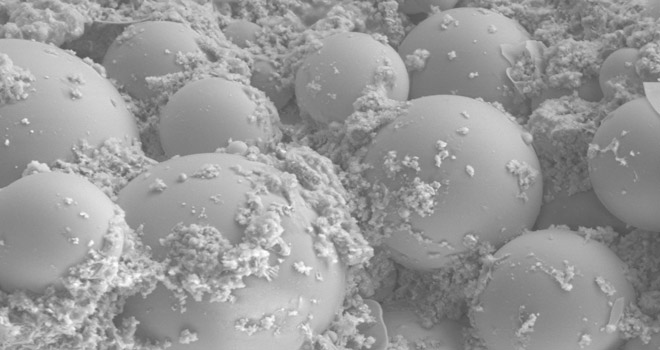

The method of application is a decisive factor in the handling of building materials, especially in times of a shortage of skilled workers. Thanks to its excellent rheological properties, ecosphere insulation for interior and exterior use is well-suited for this: Application is done in the traditional fashion from a bag or silo with a plastering machine.